Mercedes-Benz is accelerating its digital transformation, reinforcing Berlin-Marienfelde’s role as a global innovation hub for AI-driven production.

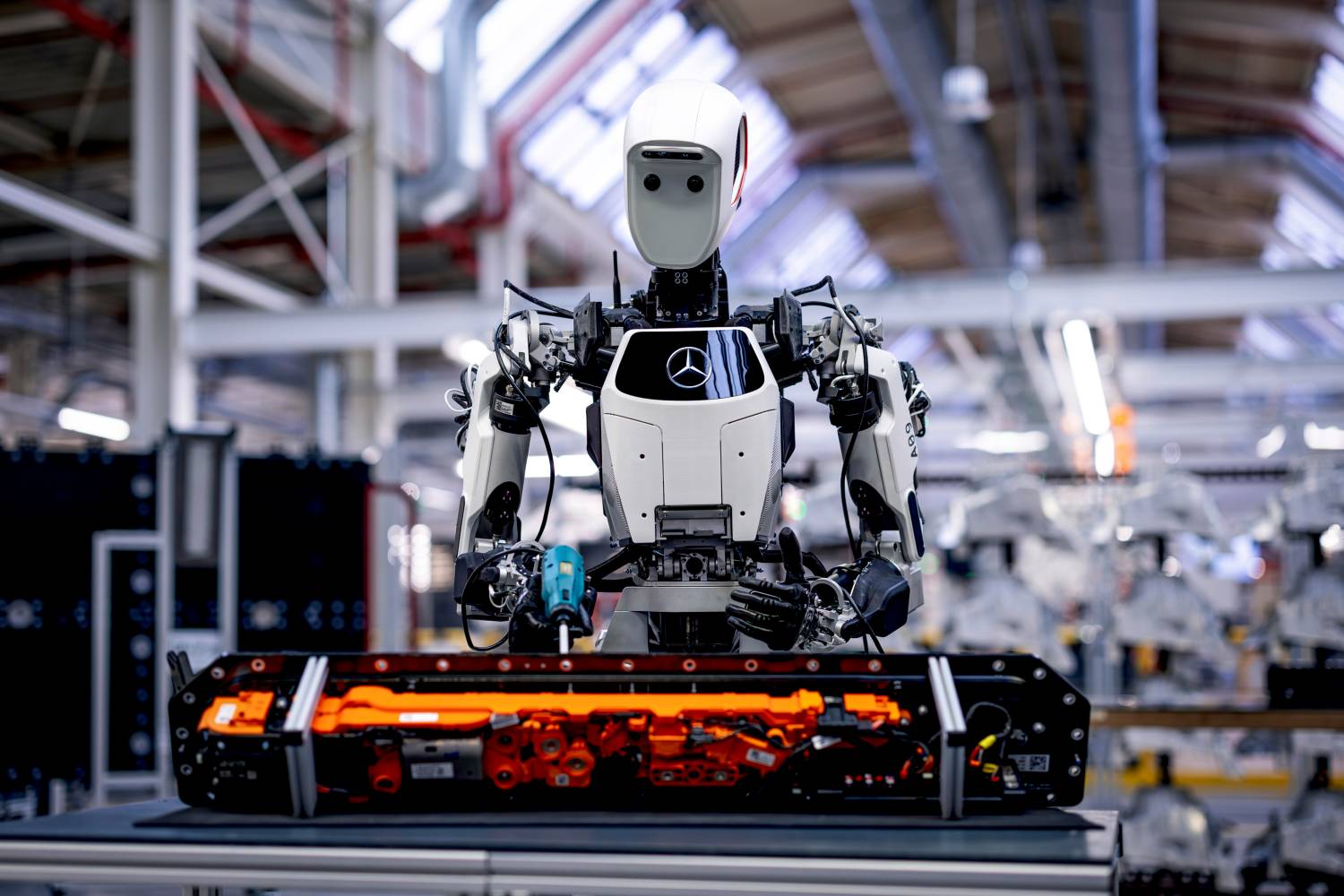

The Mercedes-Benz Digital Factory Campus (MBDFC) is now integrating AI, humanoid robots, and cutting-edge production methods, setting new standards for the company’s global network.

READ MORE: Electric Road Trip to the World’s Northernmost Fast-Charging Station

The MO360 digital production ecosystem has been enhanced with AI-powered tools like the Digital Factory Chatbot Ecosystem and MO360LLM Suite, enabling smarter, more efficient manufacturing.

The site is also pioneering the use of humanoid robots from Apptronik, with the Apollo robot assisting in logistics, quality checks, and data collection for autonomous operations. Mercedes-Benz has invested a low double-digit-million-euro sum in Apptronik to advance robotics in automotive production.

Beyond AI and robotics, Marienfelde is also leading the shift to electric mobility, becoming a center of excellence for high-performance axial-flux motors.

Production of these next-gen electric motors begins next year, with 35 entirely new manufacturing processes and 30+ patents showcasing Mercedes-Benz’s leadership in innovation.

By combining AI, automation, and advanced manufacturing, Mercedes-Benz is shaping the future of digitalized, intelligent production while reinforcing Germany’s position as a leader in automotive innovation.

READ MORE: Lexus Plug-In Hybrids: More Electric, More Efficient, and Better to Drive

Subscribe today for the freshest car news delivered to your inbox