We often overlook the small things in our cars, like doors that close smoothly, seats that adjust effortlessly, or armrest hinges that hold up after a tough day. These details might seem minor, but they’re crucial to our driving experience.

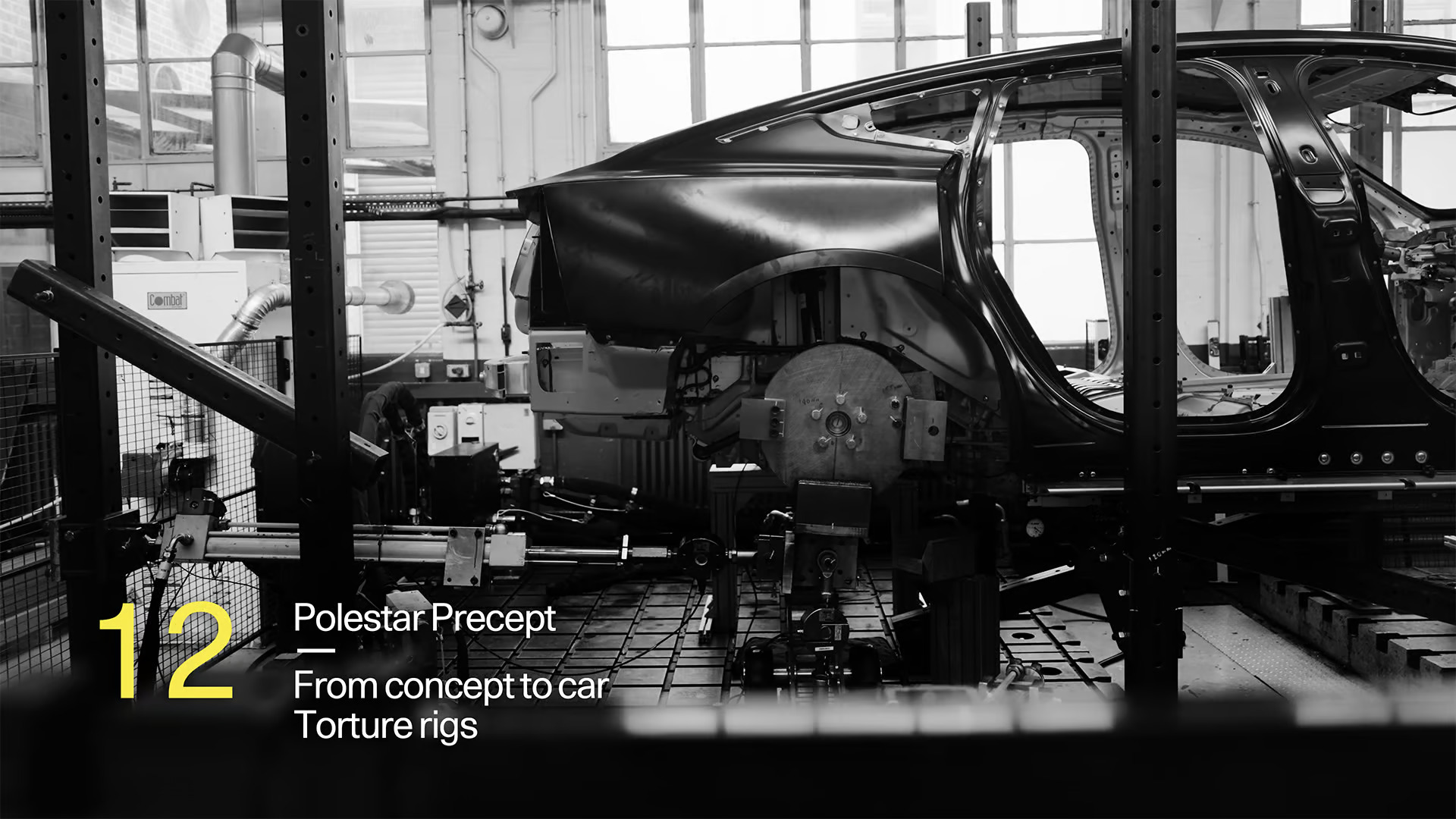

That’s where Julian Cantwell, Polestar’s Systems Validation Principal Engineer, comes in. His job is to ensure these components work flawlessly by testing them to their limits—even to the point of breaking them.

Joining Polestar in December 2020, Cantwell’s role involves subjecting car parts to rigorous testing to ensure they meet durability standards. “My job is basically to break as much stuff as possible,” he says.

READ MORE: Porsche Expands Electric Presence in Canada with New Pop-Up Locations

While this may frustrate design engineers, it’s essential for ensuring that every component is robust enough to withstand real-world use. “Our end goal is really about durability and robustness,” Cantwell explains, emphasizing that they simulate wear and tear to guarantee products exceed customer expectations.

Cantwell’s work takes place at Polestar’s test facility in the UK, where he revived a decommissioned lab into a cutting-edge testing center. His team of eight uses intricate machines, known as rigs, to replicate human actions, like opening and closing a car hood repeatedly under extreme conditions.

They also test parts against harsh weather, from freezing cold to intense heat, and expose them to dirt, grit, and other abrasive materials to simulate long-term use.

One of the more creative tests is the “Angry Partner Test,” where a door is repeatedly slammed to check for potential issues. This test, along with many others, helps the team identify weaknesses in components like suspension, bushings, and mounting points before vehicles are finalized. “We want to make sure we’ve found and changed anything unreliable, not robust or unsafe, before it goes anywhere near the track or the customer,” Cantwell says.

Cantwell’s team’s work ensures that Polestar vehicles are as reliable and durable as drivers expect, thanks to their relentless pursuit of breaking—and then improving—every part of the car.

READ MORE: F1 Rising Star Oliver Bearman Test Drives the New SF90 XX Spider on Emilia’s Scenic Roads

Subscribe today for the freshest car news delivered to your inbox