BMW Group’s Regensburg plant is using artificial intelligence to enhance quality control across its assembly lines, making inspections faster, more efficient and tailored to each vehicle.

As part of the “GenAI4Q” pilot project, the system generates individual inspection plans for up to 1,400 cars produced daily.

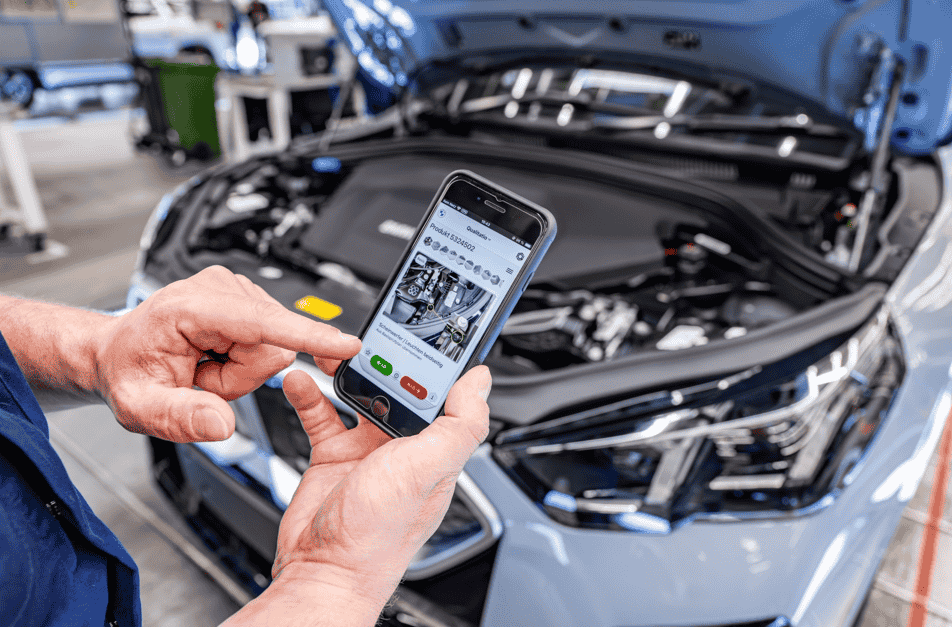

Developed in partnership with Munich startup Datagon AI, the tool analyses model and production data to recommend inspection steps via a smartphone app.

READ MORE: Hyundai Unveils New XCIENT Fuel Cell Heavy-Duty Truck at ACT Expo 2025

It also includes voice control and speech recognition for ease of use. This applies across all drivetrain types, including combustion, hybrid and electric vehicles.

“AI supports our goal of an intelligently connected factory,” said Armin Ebner, head of Plant Regensburg. “It optimises our processes and adds value for customers.”

A new car rolls off the Regensburg line every 57 seconds, with no two vehicles alike. The plant, open since 1986, produces BMW X1 and X2 models for global markets and was recently named “Factory of the Year” 2024 for large-series assembly.

Regensburg is also preparing to build BMW’s next-generation NEUE KLASSE models by the second half of the decade.

Nearby Wackersdorf supports cockpit production, exports, and is expanding with a new battery testing centre and a door and flap facility for Rolls-Royce. Together, both sites employ around 9,250 staff, including 350 apprentices.

For media inquiries: Christian Dürrschmidt – +49 151 6060 5194 – Christian.Duerrschmidt@bmw.de

Saskia Graser – +49 151 6060 2014 – Saskia.Graser@bmw.de

Source: Artificial Intelligence Enhances Quality at BMW Group Plant Regensburg

Subscribe today for the freshest car news delivered to your inbox