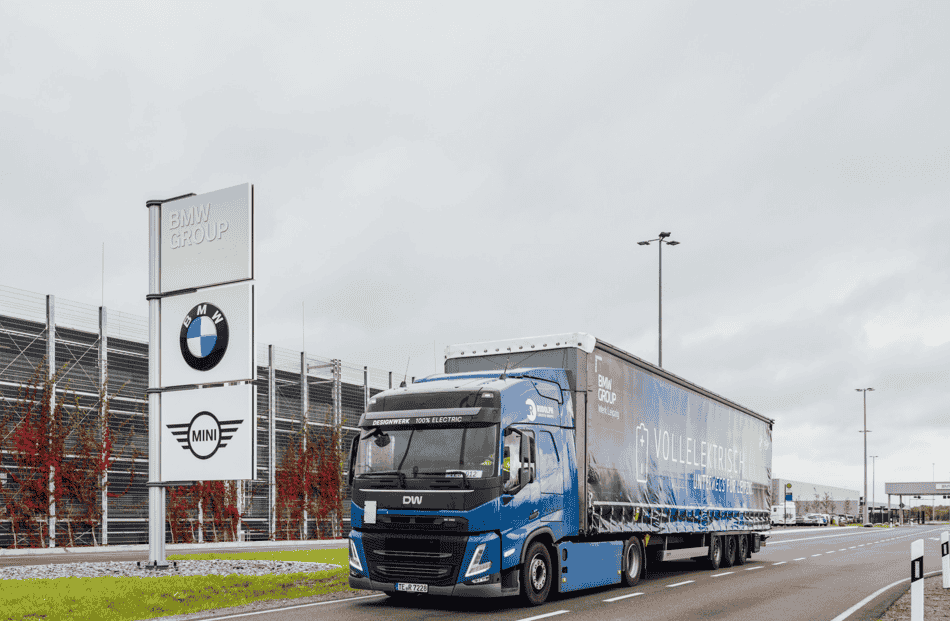

BMW Group has taken another step towards sustainable production at its Leipzig plant, introducing two fully electric trucks for transporting components. These vehicles, replacing conventional diesel trucks, are expected to save around nine tonnes of CO2 emissions annually.

The trucks handle an eight-kilometre route between the logistics centre and the plant’s high-voltage battery production halls, covering up to 100 kilometres per truck daily, without local emissions or noise pollution.

READ MORE: Lexus Sets Record Sales in Europe with 90% of Cars Sold Being Electrified Models

Their primary task is moving battery cells and modules needed for BMW’s growing electric vehicle (EV) production. The plant, which began producing e-components in 2021, has been ramping up production for the fifth-generation high-voltage batteries since early 2024. These batteries are used in models like the MINI Countryman Electric, BMW iX1, and iX2.

Plant Director Petra Peterhänsel called the introduction of electric trucks a significant milestone for the future, noting the importance of integrating sustainability not just in vehicles but in production methods and supply chains.

The trucks, made by Designwerk, are powered by lithium iron phosphate batteries, offering an environmentally friendly alternative to diesel. These trucks operate with zero local emissions, produce less noise, and are three times more efficient on the road.

BMW’s move is part of a broader Green Transport Logistics initiative, aiming to reduce transportation emissions. Alongside battery-electric trucks, the company is exploring biofuels and hydrogen as part of its goal to cut CO2 emissions by 40% by 2030.

Source: Electric Trucks: A Lower-Emissions Solution for Transporting Electric Components

Subscribe today for the freshest car news delivered to your inbox