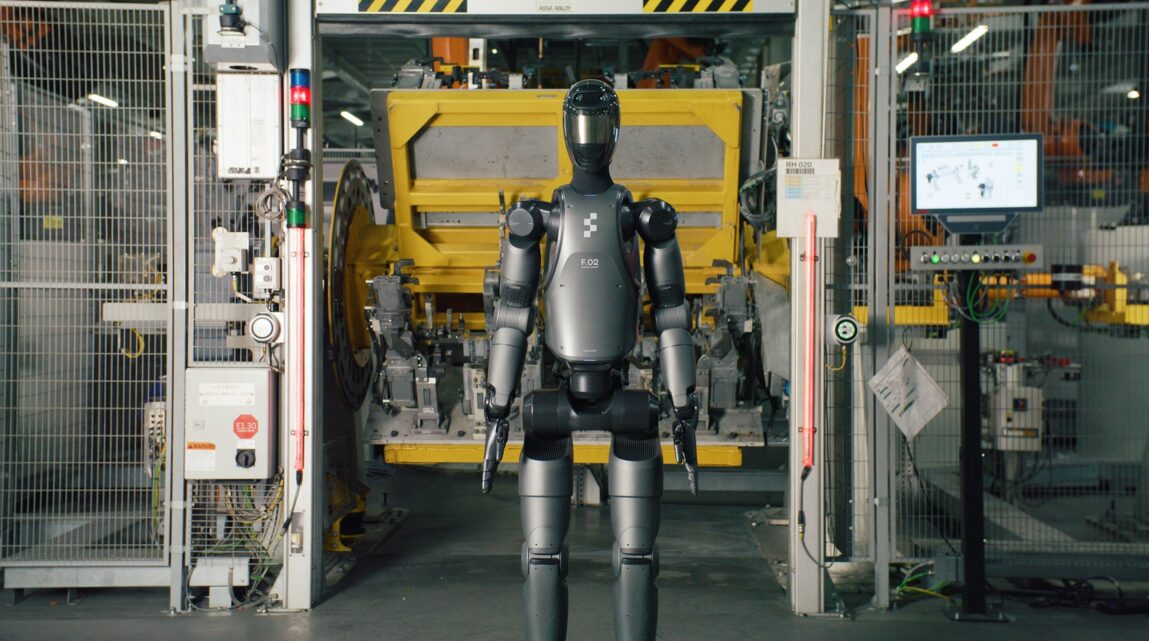

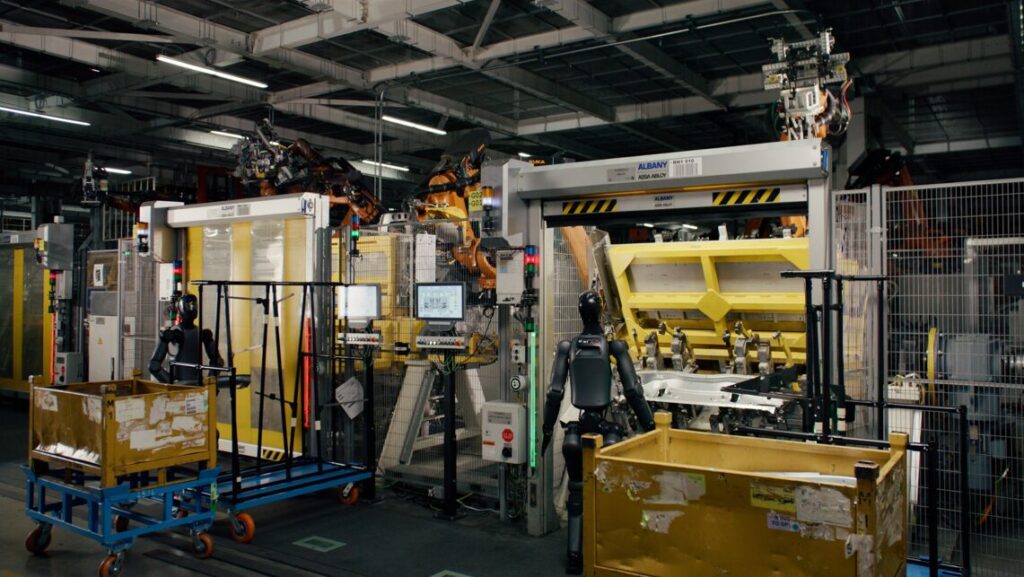

The BMW Group is breaking new ground by exploring the use of humanoid robots in its production processes for the first time. During a trial run at BMW Group Plant Spartanburg, the latest humanoid robot, Figure 02, developed by California-based company Figure, successfully inserted sheet metal parts into specific fixtures, which were then assembled as part of the chassis. This task requires a high level of dexterity, demonstrating the robot’s advanced capabilities.

The introduction of humanoid robots aims to relieve employees from performing ergonomically challenging and tiring tasks. The BMW Group, in collaboration with Figure, is currently testing and evaluating the safe integration of these robots into automobile production. A video showcasing the trial run in the body shop at BMW Group Plant Spartanburg is available here.

“The developments in the field of robotics are very promising. With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialization,” said Milan Nedeljković, Member of the Board of Management for Production at BMW AG.

READ MORE: BMW Group Wins 2024 Altair Enlighten Award for Sustainable Process

Advancing Production with Humanoid Robots

The BMW Group is always seeking new technologies to enhance its production processes, aligned with its vision for the BMW iFACTORY, which emphasizes efficiency, digitalization, and sustainability. During the trial run, the company gained valuable insights into the requirements for integrating multi-purpose robots into existing production systems. This includes understanding how humanoid robots communicate with the system under real conditions. Following the initial use in automobile production, BMW and Figure are collaborating to refine and prepare Figure 02 for future production applications, based on the findings.

Figure 02: A Leap in Robotics Technology

“We are excited to unveil Figure 02, our second-generation humanoid robot, which recently completed successful testing at the BMW Group Plant Spartanburg. Figure 02 has significant technical advancements, which enable the robot to perform a wide range of complex tasks fully autonomously,” said Brett Adcock, Founder and CEO of Figure.

Figure 02 is currently the world’s most advanced humanoid robot, combining two-legged mobility with advanced dexterity, making it ideally suited for tasks that are physically demanding, unsafe, or repetitive. This enhances ergonomics and safety for human workers. The robot features three times the processing power of its predecessor, improved voice communication, better cameras, microphones, and sensors, a high-performance battery, and fourth-generation human-scale hands with 16 degrees of freedom per hand and human-equivalent strength.

Future of Humanoid Robots at BMW

Although there are no Figure AI robots currently operational at BMW Group Plant Spartanburg, the collaboration between BMW and Figure continues. The focus remains on data capturing and training capabilities to further develop the Figure 02 robots for potential future use in production. While a definitive timetable for their deployment has not been established, the ongoing partnership aims to harness the full potential of humanoid robotics to enhance production efficiency and safety.

BMW’s commitment to integrating cutting-edge technologies like humanoid robots underscores its dedication to innovation and sustainable development in the automotive industry.

Source: Successful Test of Humanoid Robots at BMW Group Plant Spartanburg

Subscribe today for the freshest car news delivered to your inbox