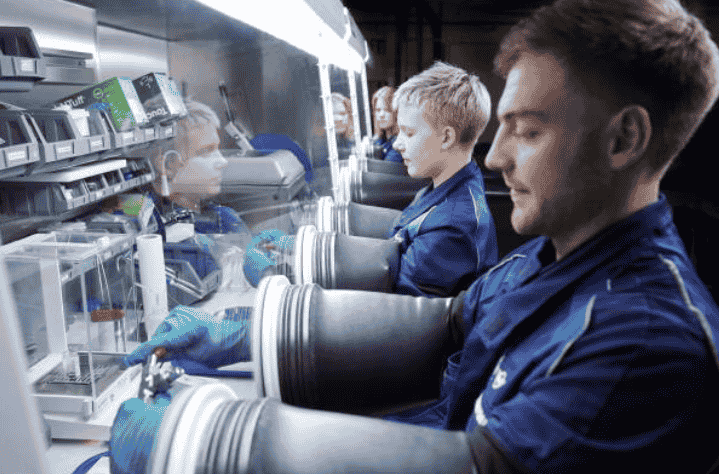

The BMW Group’s Battery Cell Competence Center (BCCC) has partnered with the University of Zagreb’s Regional Center of Excellence for Robotic Technology (CRTA) to enhance battery cell production using artificial intelligence (AI).

This collaboration aims to improve performance, quality, and cost efficiency in battery manufacturing through data-driven AI models.

READ MORE: Hyundai Celebrates Multiple Wins at IDEA 2024 for Innovative Design

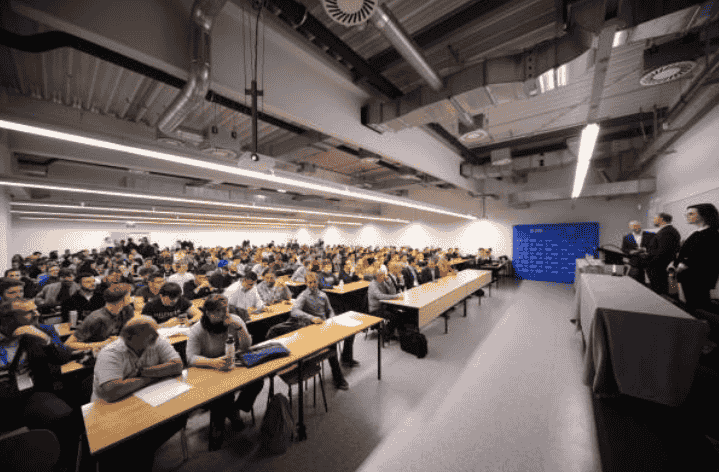

Students and researchers from the University of Zagreb are actively involved in collecting and analyzing production data. By leveraging this data, the AI models can identify patterns to predict optimal production methods.

The project fosters a close exchange of expertise between BMW and the university, combining advanced research with practical industry applications.

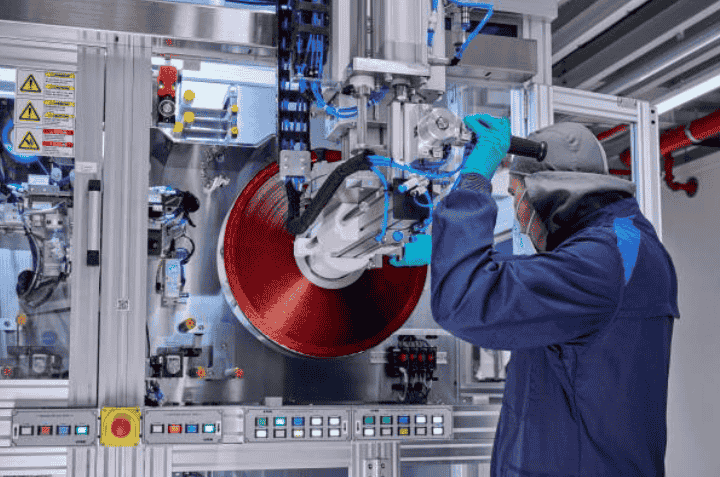

BMW’s BCCC, located in Munich, focuses on developing next-generation high-voltage batteries, while the Cell Manufacturing Competence Center (CMCC) in Parsdorf scales these innovations for series production. This comprehensive approach covers the entire value chain, linking product development with production processes.

The collaboration also aims to nurture young talent, offering students mentoring and career opportunities within BMW. The partnership strengthens European knowledge exchange, benefiting both institutions and advancing the future of battery technology.

Subscribe today for the freshest car news delivered to your inbox