Bentley Motors is celebrating a significant milestone—25 years of Additive Manufacturing (AM) at its Crewe headquarters, underscoring the brand’s long-standing commitment to innovation and craftsmanship.

What started as a support system for developing the first-gen Continental GT has since evolved into a cutting-edge, in-house 3D printing facility.

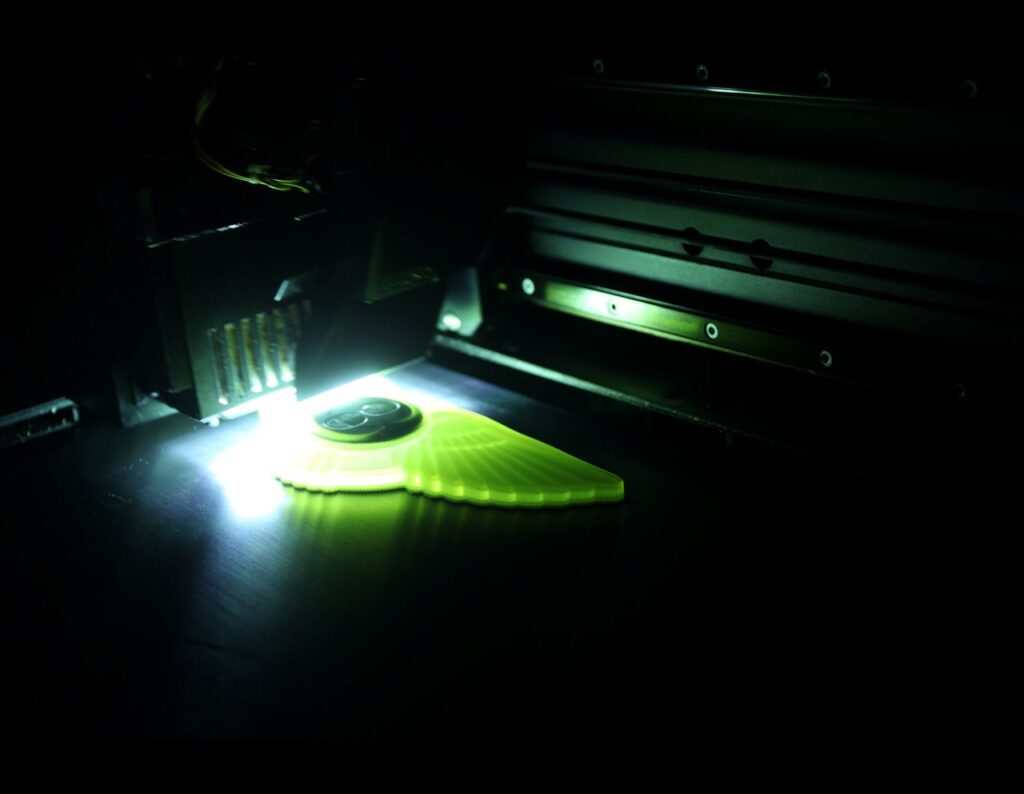

Now housed in the Engineering Technical Centre, the AM operation features 13 advanced machines across six distinct technologies, delivering high-precision parts that support every stage of development and production.

READ MORE: Robert Wickens Returns to Elite Racing with Corvette GT3.R After Spinal Injury

Initially tucked away in the historic A1 building—currently being converted into the production line for Bentley’s first battery electric vehicle (BEV)—the AM center now plays a pivotal role in Bentley’s future-forward strategy.

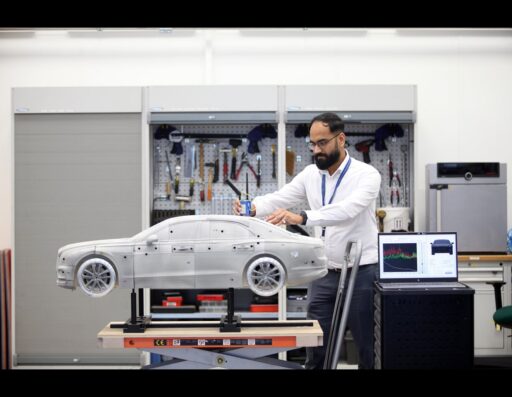

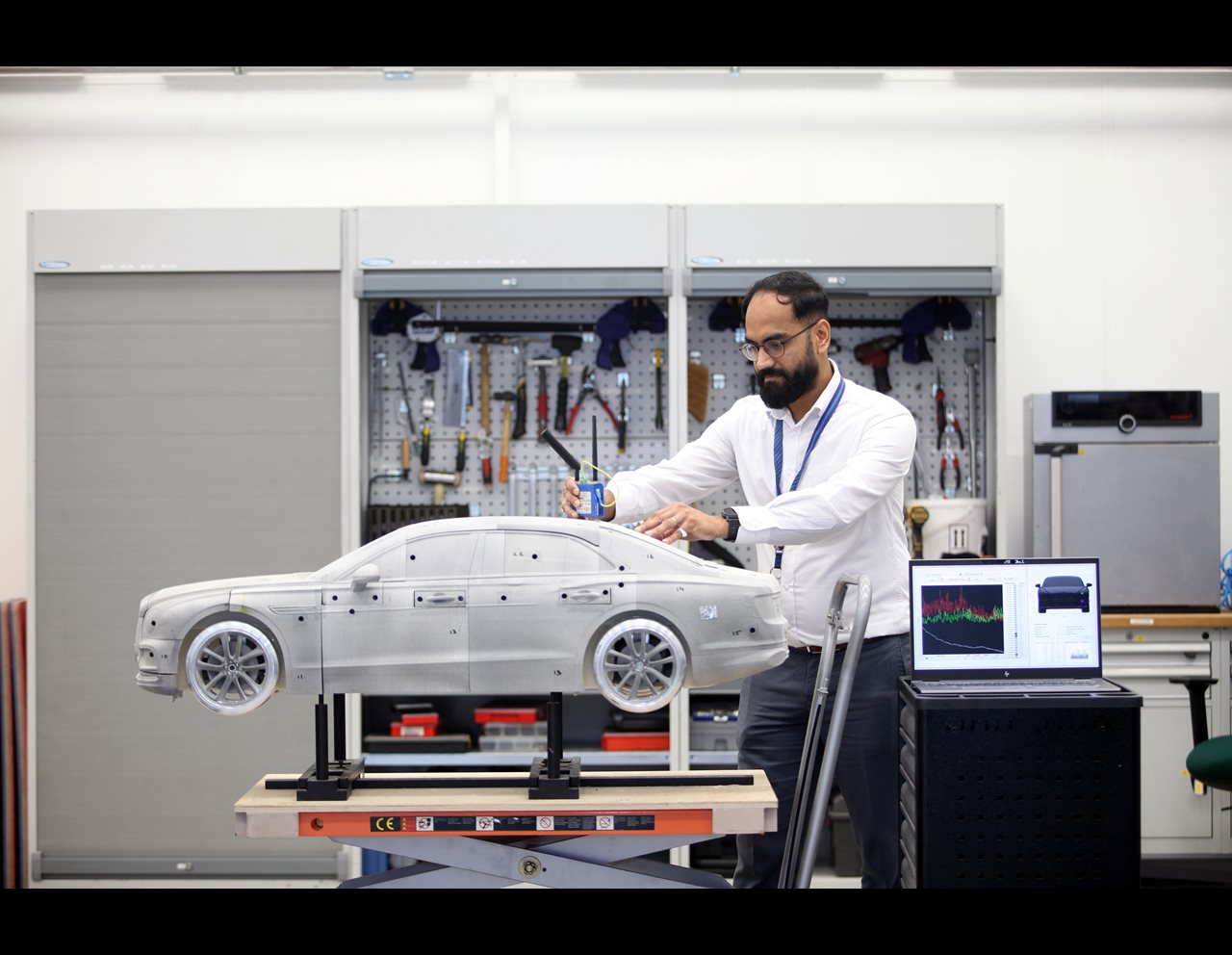

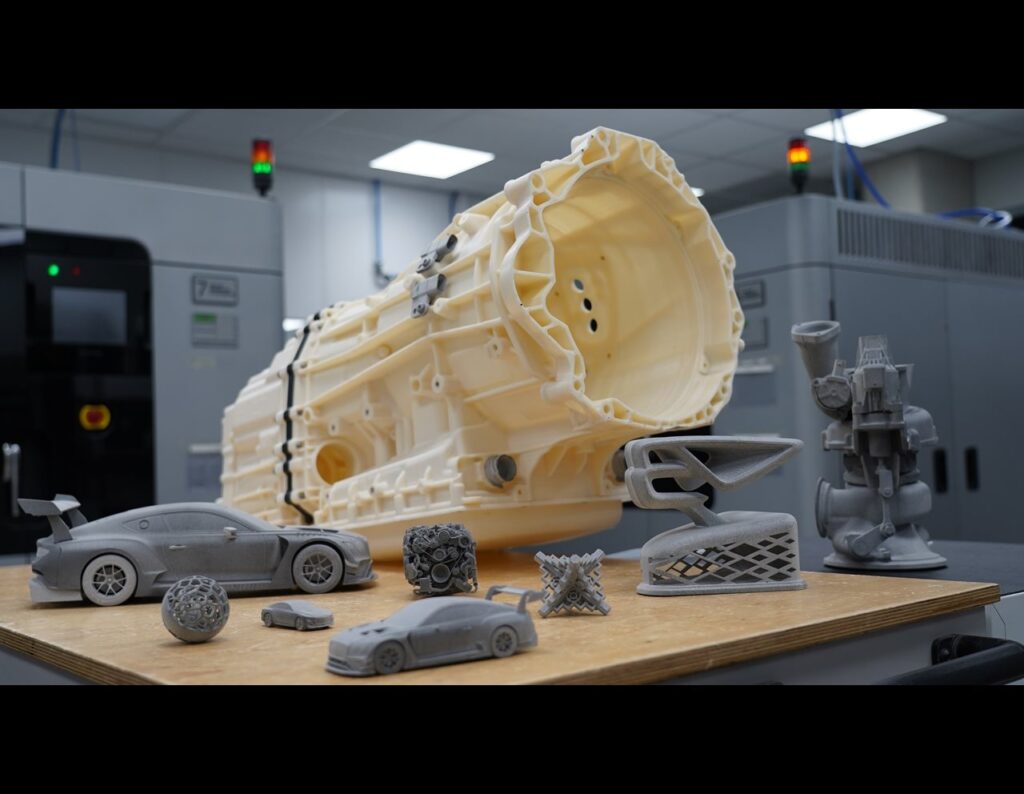

It’s not just about rapid prototyping anymore. Today, Bentley’s AM team creates everything from bespoke scale models and aerodynamic test components to fully functional, single-print parts and custom tools, helping accelerate production timelines while also reducing waste.

Highlighting just how far the technology has come, Bentley recently made waves with an industry-first use of 3D printed solid rose gold on The Black Rose, one of just three right-hand-drive versions of the ultra-exclusive Batur.

The craftsmanship involved integrating 210 grams of 18-karat gold into the vehicle’s interior—at key driver touchpoints—blending the latest tech with high-end luxury in a way only Bentley could.

Beyond the glamor of limited-edition showpieces, AM has been instrumental in Bentley’s pivot toward sustainability and community service. The facility’s team reused excess polymer powder from one process to generate new filament for another—effectively repurposing around 60% of its material output.

During the height of the COVID-19 pandemic, Bentley’s 3D printers were even repurposed to produce over 20,000 PPE items for frontline NHS workers and local care homes.

According to Dr. Matthias Rabe, Bentley’s Member of the Board for R&D, AM has become integral to their operations. “Our capability and expertise in this field has gone from strength to strength,” he noted. “It continues to transform how we design and manufacture our models—especially as we move into the electric future.”

Among the more awe-inspiring technical feats? A fully detailed W12 engine block scaled down to just 5 mm wide, printed with Lithography-based Metal Manufacturing (LMM)—a groundbreaking metal 3D printing technique that delivers extreme precision.

In short, Bentley’s AM journey reflects its blend of tradition and tech—a commitment to staying ahead of the curve while crafting cars that feel timeless.

READ MORE: Stellantis Reports Q1 2025 Global Shipments of 1.2 Million Units, Down 9% Year-Over-Year

Subscribe today for the freshest car news delivered to your inbox