Bentley Motors has unveiled a cutting-edge AI-powered Hide Inspection system aimed at transforming how leather is selected for its luxury car interiors.

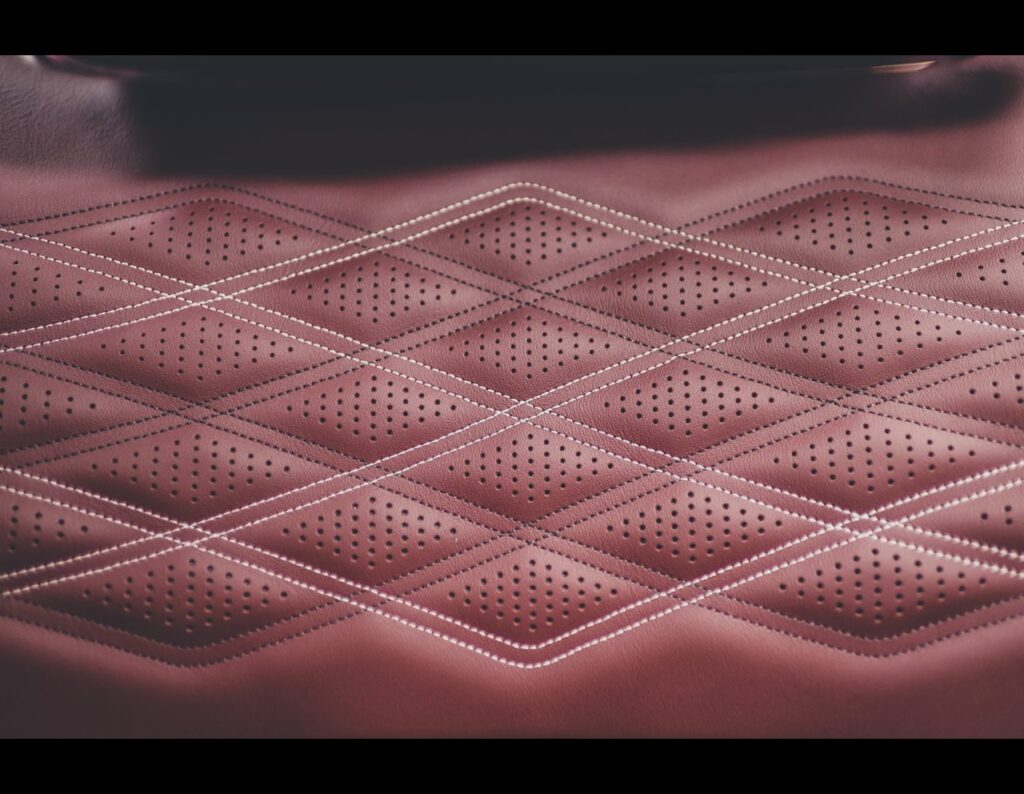

As part of the brand’s forward-looking Beyond100+ strategy, this new technology promises to enhance craftsmanship, sustainability, and efficiency—all while preserving the meticulous hand-finished detail Bentley is known for.

READ MORE: Nissan Set to Unveil All-New Model at Auto Shanghai 2025

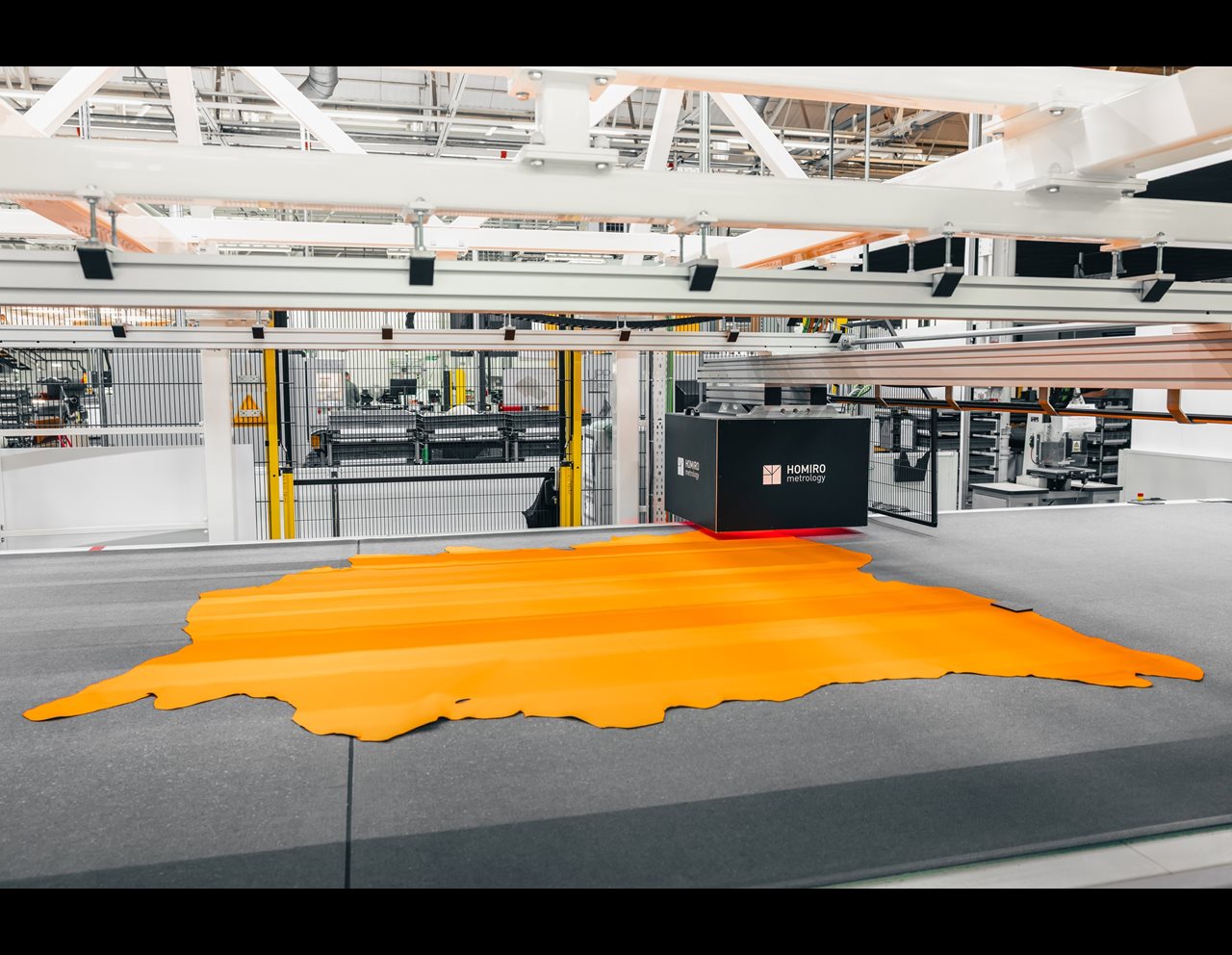

Traditionally, Bentley’s skilled craftspeople inspect each leather hide manually, a labor-intensive process. Now, with AI and advanced camera technology, imperfections such as insect bites, scars, or holes—often invisible to the human eye—can be swiftly detected.

The result is a dramatic improvement in quality control and material efficiency, particularly important given that each Bentayga SUV interior uses around nine hides.

While the AI system streamlines and speeds up the inspection phase—allowing multiple hides to be scanned simultaneously—it doesn’t replace Bentley’s artisans. Instead, it ensures only the highest-grade leather is passed on for hand-sewn detailing, preserving the brand’s signature level of craftsmanship.

This system, the first of its kind within the Volkswagen Group, integrates seamlessly into Bentley’s existing processes, optimizing the use of over 200 trim parts per vehicle. Most notably, it also contributes to Bentley’s sustainability goals, reducing CO₂ emissions by 135.7 kg per car through better material utilization and less waste.

Andreas Lehe, Bentley’s Board Member for Manufacturing, emphasized that this innovation is just one example of the brand’s larger transformation under Beyond100+, which includes the move toward digital, low-impact manufacturing and the development of Bentley’s first battery electric vehicle (BEV)—set to redefine the future of luxury mobility.

READ MORE: Retro Rides Revisited: Exploring the 1969 All-Electric GM XP-512E Concept Car

Subscribe today for the freshest car news delivered to your inbox